Tony Simoni’s Grande Hobbit Derbi Mix Race project

Words by Tony Simoni

The idea

Nate came to me in late December of 2008 and let me know of this awesome race moped idea he wants me to build. He had been waiting months for the parts for various parts to come in so he could determine what our best options. Here was Nate’s “Grande” idea:

Use a sturdy frame, light-weight motor, a variator/clutch parts that can handle power, and make a sturdy sub frame. Keep in mind I am a large guy with more weight than the average rider so large size and sturdiness was a key factor.

Major Components

Vespa Grande: Frame & integrated Gas Tank

Honda Hobbit: Cases & Rear Wheel

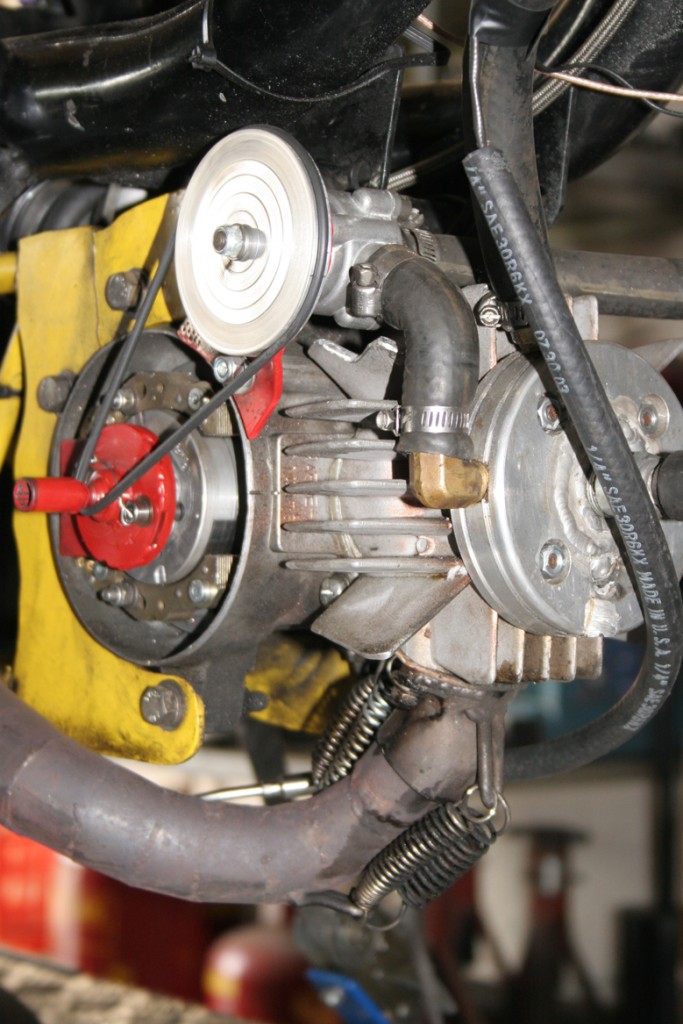

Derbi Variant (Flat Reed): Crank, Clutch, Variator (TJT), Metrakit cylinder kit

Motomatic Exhaust: Destroyer

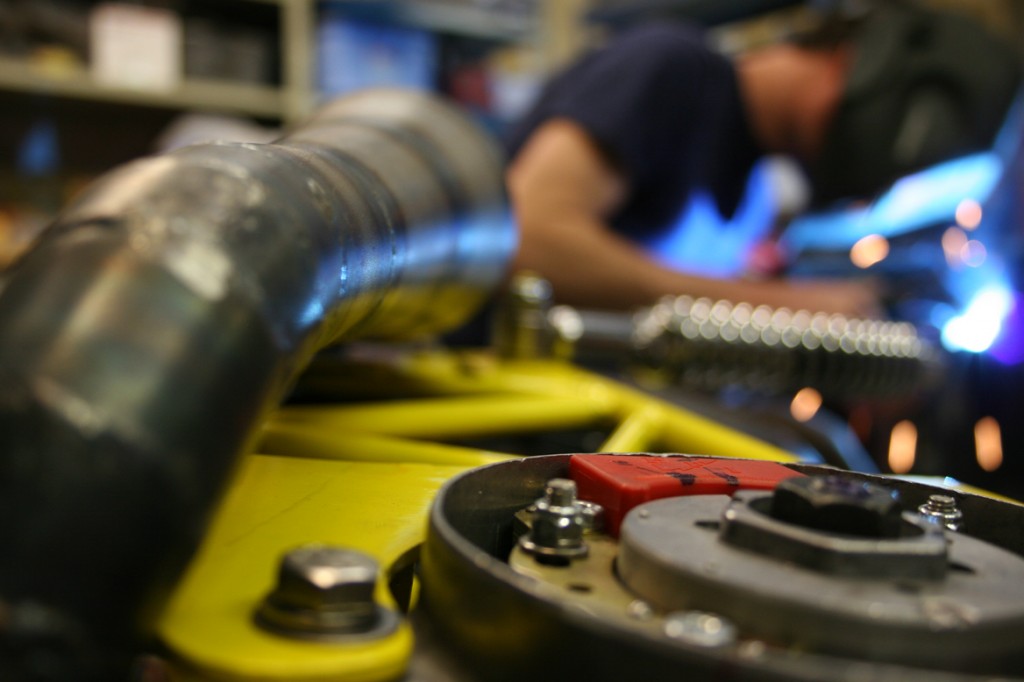

Motomatic Sub frame: Built by Nate out of thin walled 4130 steel tubing made to match a typical moped wheelbase of 44”.

Rear Shocks: Honda XR 75

Front Forks: Pit bike forks (last race used EBR race forks)

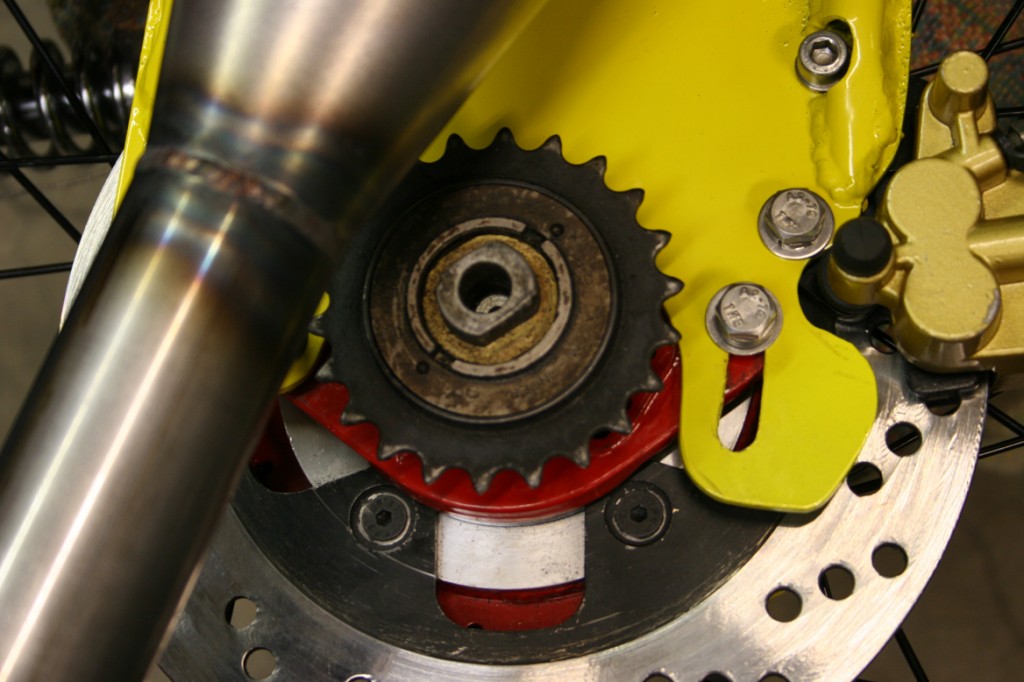

Front Wheel: 17” rim with a Motobecane hub with a pit bike disc affixed.

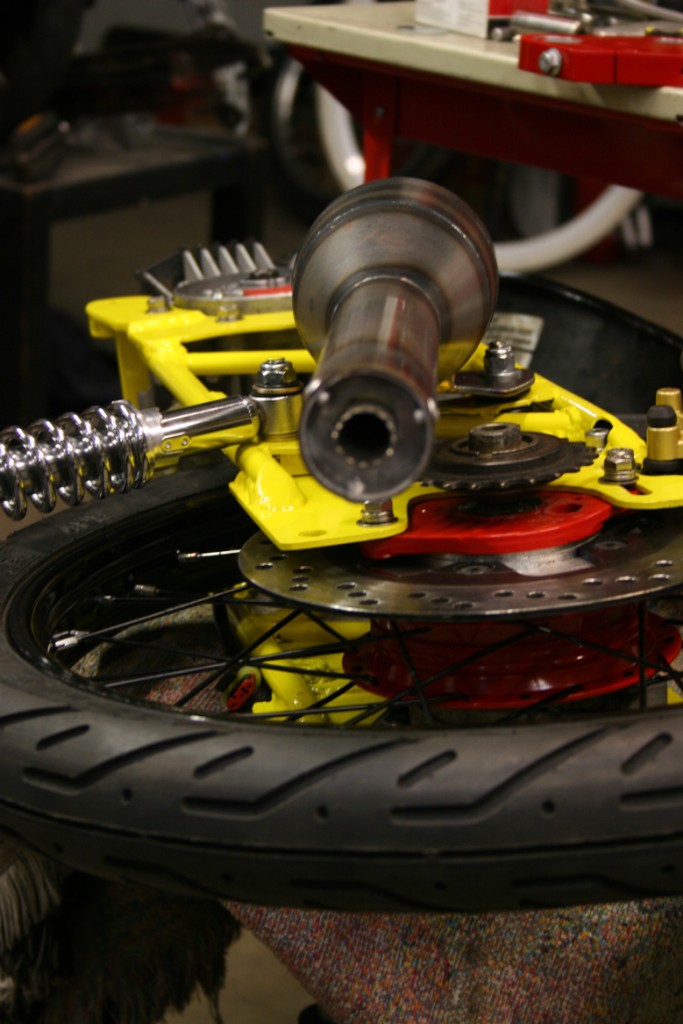

Rear Wheel: 16” rim with Honda Hobbit hub and GSXR 750 disc brake affixed.

Motomatic Powder Coating: Thank you Mike Rafter

Carburetor: OKO 21mm (changed to a 24mm)

Ignition: HP1 Puch ignition

The assembly:

In addition to the assembly of these key parts much effort was put into how to get these parts to work together.

• The sub frame had to be offset to ensure the drive belt was aligned

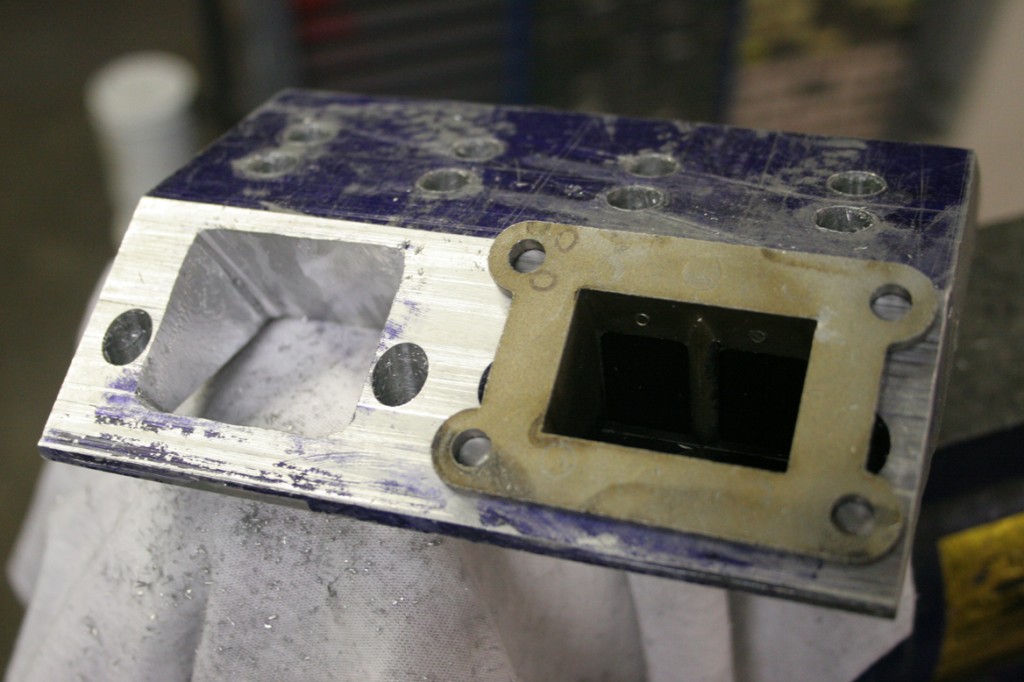

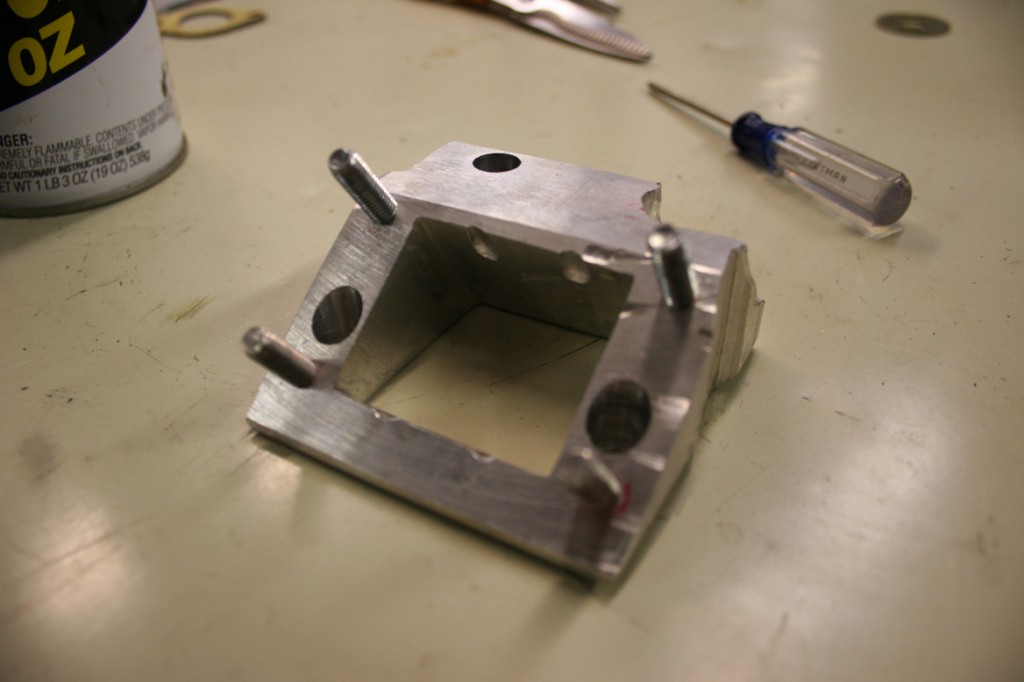

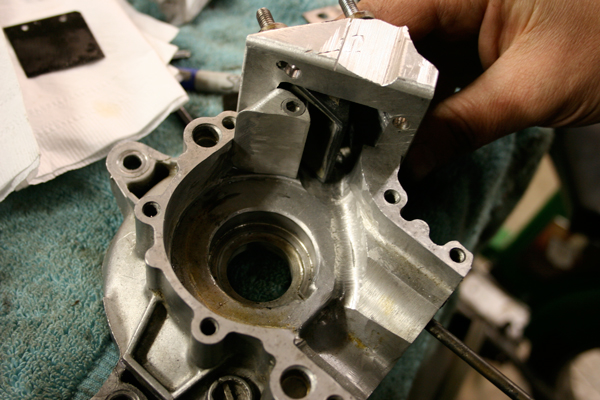

• A special reed cage manifold was made to squeeze the largest reed cage (Gilardoni) within the stock mounting stud pattern and yet still have the reed pedal close as possible to the crank case and also direct flow directly into the transfer ports.

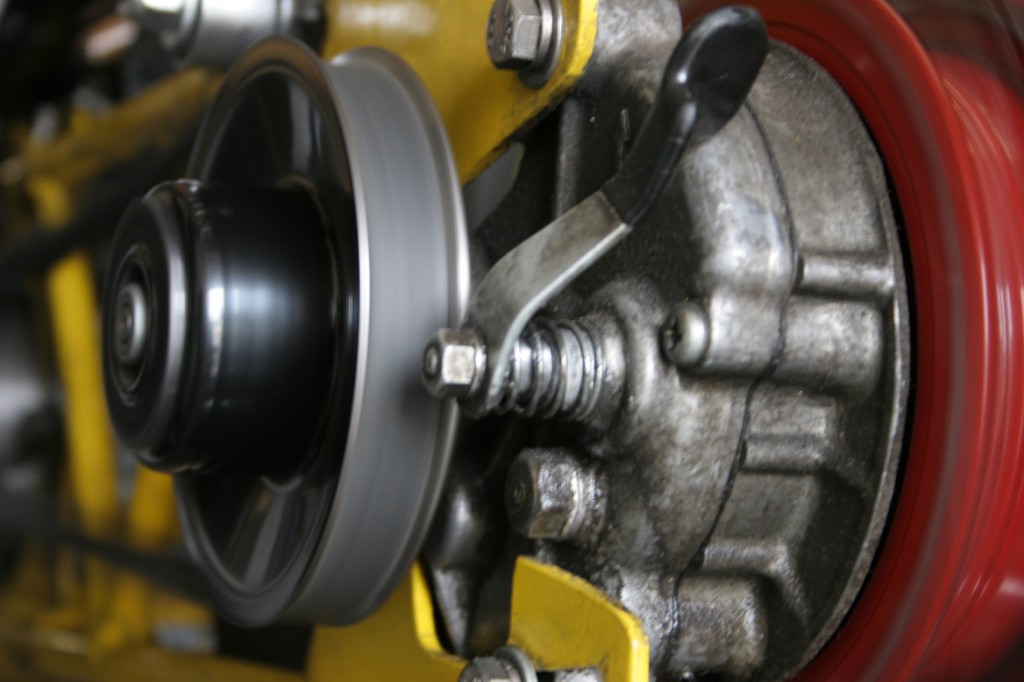

• The rear Honda Hobbit torque driver was modified so it can match the variation (movement) of the Derbi Variant Variator.

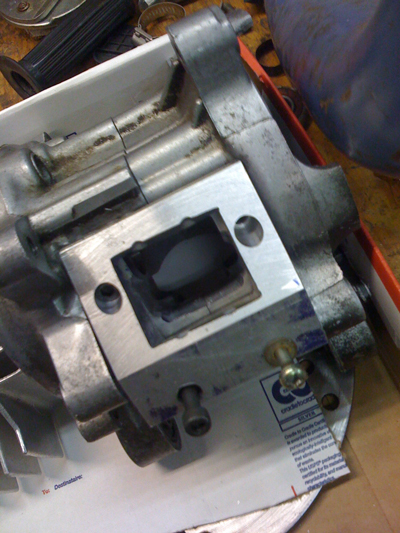

• The HPI ignition needed the taper re-machined for a good fit, the hobbit cases needed to be machined to fit the seals and Puch stator plate, and a stator plate base needed to be machined. 10 hours spent here.

• A custom seat had to be supported and fabricated. (Thanks to Nate)

• The 70cc Metrakit kit needed slight modification of the stud holes and small amount of epoxy was used on the cases to match the stock Metrakit base gasket shape. Also, a 1mm base gasket was used to keep 1mm clearance between the piston and head.

Tuning the Machine

Race #1 & 2 – Initial Motor Development:

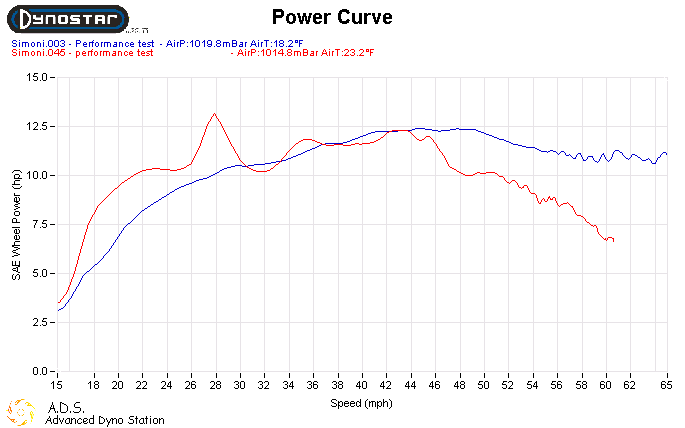

Out of the box with no porting just minor case matching the 1st time we rode the machine it did 64 MPH with very little jetting. It later dyno’d at 10.5 HP at 9,500 RPM.

Race #3 – cooling issues:

The porting inside the kit became extensive and the head was re-profiled to raise the compression. The engine ran head temperatures exceeding up to 475 F, so an air duct was fabricated to direct air across the head. A wheelie was achieved and the moped became very fun to ride. 58 MPH was achieved at the end of the Atwater straight-away. The moped dyno’d close to 13 HP at 11,500 RPM, but the clutch was having issues engaging which yielded inconsistent dyno readings.

Race #4 – starter clutch removed:

the starter clutch was removed to avoid rough inconsistent take-offs. The moped became a real competitor. However, after the 2nd lap head temperatures began to rise above 400 F and the end of the Atwater straight-away speeds dropped to 52 MPH.

Race #5 – the power is all there:

The cylinder was raised 1mm, an experimental pipe was used, and the resulting engine speed was ramped up to 13,500 RPM. A water-cooled head was fabricated to cure the cooling issues. 60 MPH was achieved at the end of the Atwater straight-away. The moped dyno’d at a consistent and strong 12 HP.

Road speed test with stock rear gears 69 MPH

Road speed test with Malossi rear gears 73.8 MPH

Red line is super peaky power configuration as run during Polini Cup race Three. Blue line is smoother power overall as configured for the last race of the season.

OG moped hubs modified to accept disk breaks

Some color for good looks

Powdercoated spokes

GSXR Disk Super close tolerances

Mock up

Mocked up and stood up

First pipe getting fitted

Sub frame

Sub frame

Yellowed up

Yellowed up

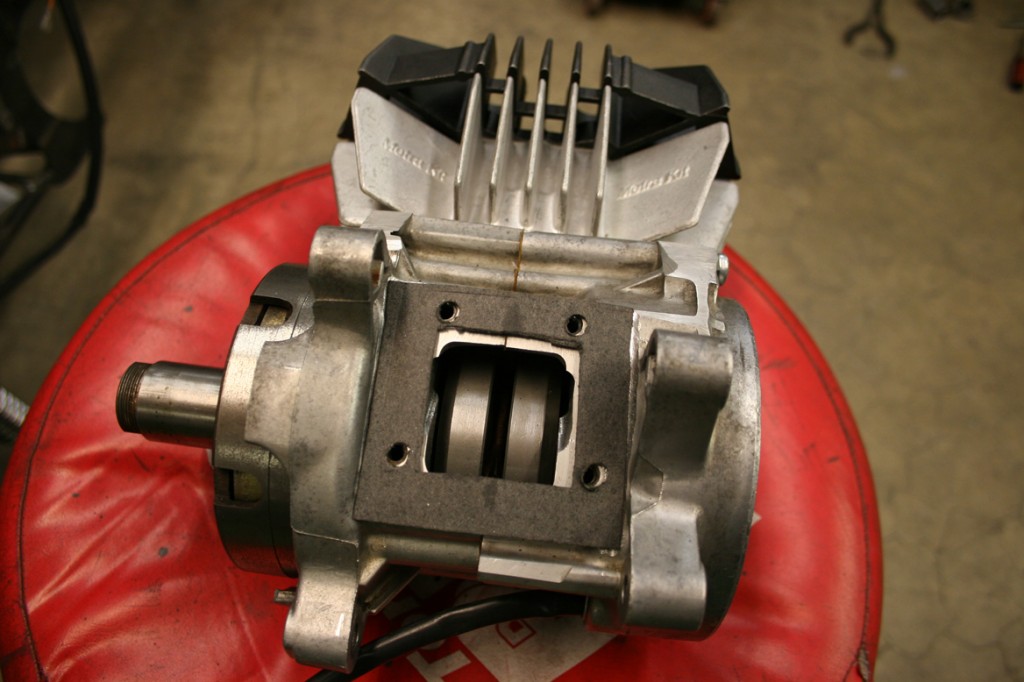

Everyones favorite cases

Can't buy this reedblock at your local corner store.

Gila reeds fitted in

Ready to bolt on

Snug fit

Two large pedals flow better than 4

Look just below the reedblock. Tony reduced crankcase volume by adding a block of Alu and improved flow.

Add a wing to the reed block to keep things flowing

HPI

Late nights

Big gun

Built in some adjustment

Does it even fit in the oven?

First time loaded up to hit the farm roads for testing

Stock vs modded rear variators

This steel can take a lot of time to hack at. Shit is tough.

Springs are also a pain

More working out variation

Pretty

Clutch bell and TJT lathed down for less rotating mass

Powdercoat it for good measure

Water pump parts made from scratch

Good dyno results make Tony's thumb go up.

Belt riding high for happiness

Aircooled pipe testing

Pinning the throttle and maxing RPMs

17 inch rim swapped for 16 inch rim for a better tire. Pirelli 2.75

Spring mounted pipes make for quick changes while Dyno testing

DR. Pully sliders. TJT wieghts self destuct quickly and get all flatspotted.

TJT plus DR. Pulley

So many pipes so many powerbands

Red Rocket pipe is funny fun and fast

Hella bells and whistles. Custom water cooled head Tony made from a block of Alu

13415 RPM !!!! I'd say thats on the high side 11.1 horse power 68.3 mph on the dyno.

Tony gassing up the bike for road speed test with Terry Dean Cain as driver.

No overheating and great speed results

Duck Down

18 Responses so far

PT

November 18th, 2009

11:20 pm

goddamn guys, amazing. that watercooled head is outtaaa hand!! wow.

zack

November 18th, 2009

11:49 pm

rad! This bike is nuts. I can’t wait to see what comes next.

mattoloRIPRIP

November 19th, 2009

2:47 am

YEAHHH!!!!!! BRINGIN IT

Nash

November 19th, 2009

3:03 am

just the update ive been waiting for…..great stuff. keep it coming.

tdc pinascokitten

November 19th, 2009

4:08 am

yeah! 74mph!!

jOHNNYdOUBE

November 19th, 2009

6:53 am

I love the weights, and the larger pulleys.

I will have dreams of the disc brakes and sub-frame tonite.

Were there videos of it runnin’.

I love it.

jeremy bandit

November 19th, 2009

11:11 am

amazing work! the amount of customizing is almost beyond belief. you guys are true wizards.

threehighshawn

November 19th, 2009

1:04 pm

ummm……….fuck.

PDR MCBC

November 19th, 2009

4:51 pm

So sick.

Just curious, since you have a liquid cooling setup on this bike anyway, why did you choose a Derbi aircooled kit versus a Minarelli horizontal LC cylinder?

Orphan Phrick

November 21st, 2009

9:06 am

Everytime I look at the swingarm/rear brake/wheel mount settup I am just in AWE!!!!!

Well done fine Sirs!

IRE Phil

November 22nd, 2009

7:35 pm

Awesome work dudes! Wish I could come out and learn some shit.

Jordi Giné

November 25th, 2009

7:34 am

Hi boys! very nice project!!

I love when someone is taking Derbi stuff abroad Spain to build good ways, jeje..

Greeting

Jordi from Barcelona (Spain)

supreme commander benji

November 28th, 2009

5:02 pm

you guys are sooooo amazing !!!!! lotsa love from treatland

terrydean

February 5th, 2010

3:52 am

“Just curious, since you have a liquid cooling setup on this bike anyway, why did you choose a Derbi aircooled kit versus a Minarelli horizontal LC cylinder?”

motomatic is trying to stay away from using scooter parts. using scooter parts is cheating and too easy!

jonah

May 24th, 2010

7:37 pm

ha, thought that pulley on the right side was a turbocharger when i first watched the video..

Guido Samson

December 16th, 2010

10:07 am

I love those 2 t bikes. I personally tune bikes and build pipes.A friend of mine here has 3 of the puch 50cc engines. I told him lets tune them and get them on the road. He told me it’s not worth it. the engine is too simple.Keep up the good work and please post longer and more video’s.

All the bets Guido Samson from Suriname south America

PS. Check youtube and type in Suriname racing.

Ron

January 18th, 2011

7:36 am

Please, can you help me find paint for my yellow Honda Moped Hobbit? Thanks.

Ron

Shawn

February 22nd, 2011

6:14 pm

what does modifying the rear pulley system do for variation?

Leave a comment